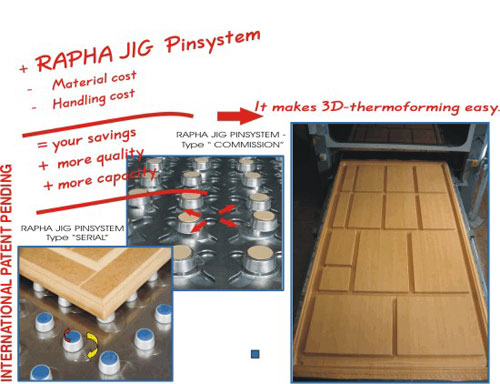

Commission Pinsystem

THE NEW PINSYSTEM FOR 3D-LAMINATING PRESSES

FOR 3D-LAMINATING PRESSES

USING OUR KNOW HOW TO MAKE IT EASY

With a few hand movements you can arrange the workpieces with the RAPHA JIG.

Pins support the work replacing the need for the many different jigs. Exposed pins can be easily positioned as counter force to avoid foil pinching on the corners instead of searching for filler pieces.

From our long experience in foil pressing and the use of computer design technology we have developed the slightly magnetised pins used on the RAPHA JIG.

Every pin can be used to support workpieces of any size. To meet the requirements of all press manufacturers and users of the RAPHA JIG the pins are available in three heights - 12, 15 and 18 mm.

MORE about the many advantages of the RAPHA Jig pinsystem

-

Retro-fitted manual for installation in 3D laminating presses

-

High precision, mechanical design for absolutly foolproof operation

-

Minimal installation and service cost because electronic, pneumatic and hydraulic components are not involved

-

Free allignment of the pins ensures complete flexibility

-

Absolute improvement of the vacuum power - the whole vacuum can take effect under the press-part (which otherwise the tie- plates cover up)

-

No standstill times of the press (because missing tie-plates)

-

Avoiding parts of waste produced by including dust under the foils

Dig for answers:

The pinsystem is also offered in following versions:

Type “STARTER”

Type “COMMISSION”.

In difference the pinsystem SERIAL has a closed surface and the pins are stronger magnetic. The rotary pins are fixed on rotating plates. Both systems were tested sucessfully and durable and it fullfills the high advantages of an updated technology.

AVAILABLE FILMS (wmv-format):

Commission (5,3MB)

Serial (5,4MB)

Serial Realtime-Processing (2,9MB)

|