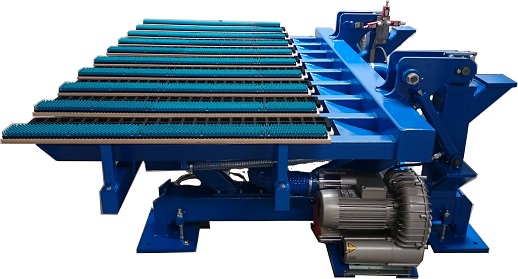

RAPHA Turn-Over System RDW for 3D-Presses

Function:

IIf the feeding tray of

the press is in position, the work piece carpet is pressed

under the holding device.

With the vacuum it is hold in position and rotated by 180°.

Then the vacuum turns off and the work piece carpet is turned

and the applied charge will be processed directly on the turn

over device.

Advantages:

• The 3D-thermoforming productivity

increases- because of quick clearing the table

• Savings of time and staff - the preliminary cutting-out

of the pressed parts is removed completely

• Simple handling of the boards

• The foil edges of the 3D furniture doors are not damaged,

because the foil is not pulled over the edge of the door

• Automatic transfer of the whole carpet to a carpet trimming

machine is optionally available.

• The pins will be protected with this turn over system because

the cutout of the over standing foil is made not on the pin

table.

Construction:

• Rigid welded frame construction

to accommodate the machine parts

• Standard size 2800 x 2220 mm x 1200 mm or according to customer

requirements

• Hydraulic power unit

• Turn table consisting of 9 arms with a special surface of

rubber

• Vacuum system with hose connections for the turn table

• Turning cycle approx. 18-25 seconds

• Installed power: approx. 8 kW

• Control System: Siemens LOGO

• Protective fences and security devices

Video

mpeg

Youtube

Link

|